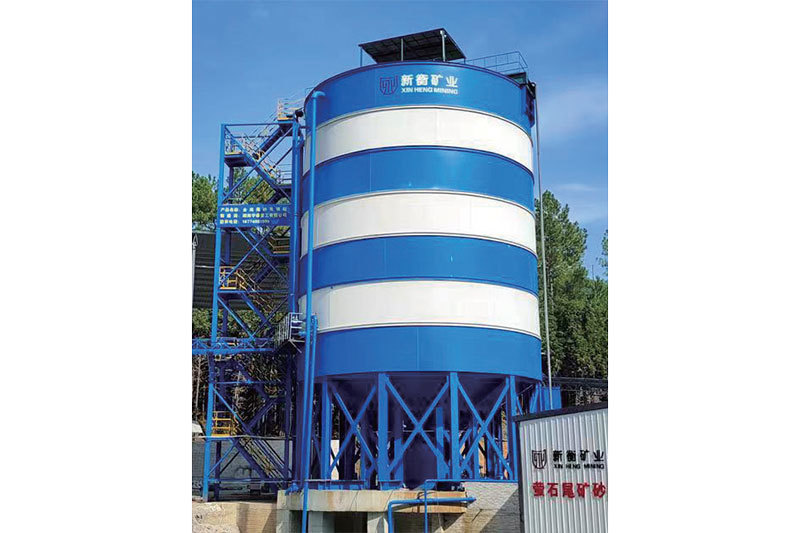

Deep cone dense machine

Key words:

Classification:

Attachments:

Product Introduction

The deep cone paste thickener uses the gravity sedimentation of solid particles in the tail mortar for continuous thickening. Its structure has a special feed well, large height-diameter ratio and cone angle, so it can produce a high concentration of underflow. The deep cone thickener is mainly composed of thickener shell, central feeding well device, mixing rake device, feeding dilution device, flocculant dosing device, self-circulating device and automatic control system.

The drive system of the deep cone thickener is a central drive device with 4 drive units, including hydraulic motors, planetary gear reducers, small gears, and large gears. The core components of the thickener adopt advanced gear design and manufacturing technology, and the system control adopts PLC and touch screen control. The drive system has overload protection, sound and light signal alarm function, can detect the torque, reliable and durable.

Yutai thickener has been used for filling in many mines with good reliability and can be made into paste slurry, and the effect can meet customer satisfaction requirements.

Products can be customized according to user needs.

Product model and technical parameters

|

Specifications |

NXZS-7 |

NXZS-9 |

NXZS-12 |

NXZS-14 |

NXZS-16 |

NXZS-20 |

NXZS-22 |

NXZS-25 |

|

Concentration tank diameter |

Φ7m |

Φ9m |

Φ12m |

Φ14m |

Φ16m |

Φ20m |

Φ22m |

Φ25m |

|

Bottom slope of concentration tank |

30 °/45 °/60 ° (selected according to the experimental data of tailings characteristics) |

|||||||

|

Side wall height |

6m |

8m |

10m |

12m |

||||

|

Slab thickness of pool body |

10/8mm |

12/10mm |

12/10mm |

16/10mm |

16/12/10mm |

16/12/10mm |

18/12/10mm |

18/12/10mm |

|

Leg Type |

Three circles inside and outside |

Four circles inside and outside |

||||||

|

Underflow barrel diameter |

2m |

2m |

2m |

2m |

2m |

2.5m |

2.5m |

2m |

|

Bottom flow barrel plate thickness |

12mm |

16mm |

18mm |

|||||

|

Meet the media |

tailings |

|||||||

|

feed concentration |

0-25% |

|||||||

|

Feeding method |

Center barrel tangent feeding (forced dilution) |

|||||||

|

settlement mode |

flocculation sedimentation |

|||||||

|

Processing capacity |

≥ 300t/d (dry ore content) |

≥ 600t/d (dry ore) |

≥ 1000t/d (dry ore content) |

≥ 1500t/d (dry ore content) |

≥ 2000t/d (dry ore content) |

≥ 3000t/d (dry ore content) |

≥ 4000t/d (dry ore content) |

≥ 5000t/d (dry ore content) |

|

ore discharge concentration |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

|

Solid content of overflow water |

≤ 300ppm |

≤ 300ppm |

≤ 300ppm |

≤ 300ppm |

≤ 300ppm |

≤ 300ppm |

≤ 300ppm |

≤ 300ppm |

|

Drive mode |

Center hydraulic drive |

Center hydraulic drive |

Center hydraulic drive |

Center hydraulic drive |

Center hydraulic drive |

Center hydraulic drive |

Center hydraulic drive |

Center hydraulic drive |

|

Drive motor power |

11kw |

15kw |

22kw |

22kw |

30kw |

30kw |

37kw |

37kw |

|

Rake speed |

0.06~0.2r/min (adjustable) |

0.06~0.2r/min (adjustable) |

0.06~0.2r/min (adjustable) |

0.06~0.2r/min (adjustable) |

0.06~0.2r/min (adjustable) |

0.06~0.2r/min (adjustable) |

0.06~0.2r/min (adjustable) |

0.06~0.2r/min (adjustable) |

|

Control mode |

Automatic Manual |

|||||||

1. The product pictures, product technical parameters and configurations on the above pages are only for illustration. The physical effects (including but not limited to appearance, color, size) and product technical parameters and configurations may be slightly different. Please refer to the physical product. The equipment on the other picture may include additional equipment.

2. In order to provide as accurate product information, specifications and parameters as possible, Yutai Heavy Industry may adjust and correct the text expression, picture effect and other contents of the above page in real time to match the actual product performance, specifications, index, spare parts and other information.

3. Due to real-time changes in product batches, production and supply and other factors, if the above modifications and adjustments are necessary, no special notice will be given. Please consult us for relevant information.

Key words:

Previous Page

Next Page

Previous Page

Next Page

Related Products

Related Products

Welcome your message consultation