Unpowered Deep cone dense machine

Key words:

Classification:

Attachments:

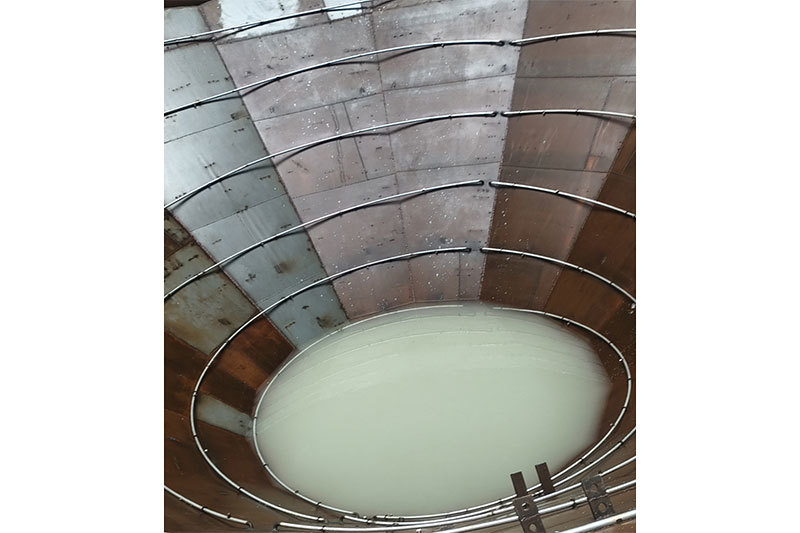

Product Introduction

The unpowered deep cone thickener uses the gravity sedimentation of solid particles in the tail mortar for continuous thickening. Its structure has a special feed well and a larger height-to-diameter ratio than the deep cone thickener, so it can produce a high concentration of underflow and store more slurry. The unpowered deep cone thickener is mainly composed of thickener shell, central feeding well device, flocculant adding system, multi-stage drainage system, compressed air slurry making system, etc.

Products can be customized according to user needs.

Product advantages

♦Large storage capacity and low energy consumption

♦Risk of high underflow concentration and no pressure rake

♦Adaptive all particle size tailings

Our core technology

♦The central cylinder rotary cutting feeding technology solves the problem of where and how the slurry enters.

♦The use of MONO screw metering pump solves the problem that the molecular chain of the flocculant is easily broken.

♦Reasonable structure of height-to-diameter ratio, higher height, greater storage capacity, higher underflow concentration.

♦Optimized design of the bottom cone angle, the bottom flow concentration is higher.

♦Multi-stage drainage system, more stable underflow concentration, more homogeneous discharge

Product model and technical parameters

|

Specifications |

NDT-8 |

NDT-9 |

NDT-12 |

NDT-14 |

NDT-16 |

NDT-20 |

NDT-22 |

NDT-25 |

|

Concentration tank diameter |

Φ8m |

Φ9m |

Φ12m |

Φ14m |

Φ16m |

Φ20m |

Φ22m |

Φ25m |

|

Bottom slope of concentration tank |

30 °/45 °/60 ° (selected according to the experimental data of tailings characteristics) |

|||||||

|

Side wall height |

14m |

14m |

16m |

18m |

20m |

25m |

25m |

25m |

|

Slab thickness of pool body |

10/8mm |

12/10mm |

12/10mm |

16/10mm |

16/12/10mm |

16/12/10mm |

18/16/12/10mm |

18/16/12/10mm |

|

Leg Type |

Three circles inside and outside |

Four circles inside and outside |

||||||

|

Meet the media |

full grain fraction |

|||||||

|

feed concentration |

0-25% |

|||||||

|

Feeding method |

Center barrel tangent feeding (forced dilution) |

|||||||

|

settlement mode |

flocculation sedimentation |

|||||||

|

Processing capacity |

≥ 300t/d (dry ore content) |

≥ 600t/d (dry ore) |

≥ 1000t/d (dry ore content) |

≥ 1500t/d (dry ore content) |

≥ 2000t/d (dry ore content) |

≥ 3000t/d (dry ore content) |

≥ 4000t/d (dry ore content) |

≥ 5000t/d (dry ore content) |

|

ore discharge concentration |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

65%~72% |

|

Solid content of overflow water |

≤ 200ppm |

≤ 200ppm |

≤ 200ppm |

≤ 200ppm |

≤ 200ppm |

≤ 200ppm |

≤ 200ppm |

≤ 200ppm |

|

Pulping pressure |

0.4MPa |

0.4MPa |

0.6MPa |

0.6MPa |

0.8MPa |

0.8MPa |

0.8MPa |

0.8MPa |

|

Pulping gas volume |

10m³/min |

10m³/min |

10m³/min |

20m³/min |

20m³/min |

20m³/min |

30m³/min |

30m³/min |

|

Control mode |

Automatic Manual |

|||||||

1. The product pictures, product technical parameters and configurations on the above pages are only for illustration. The physical effects (including but not limited to appearance, color, size) and product technical parameters and configurations may be slightly different. Please refer to the physical product. The equipment on the other picture may include additional equipment.

2. In order to provide as accurate product information, specifications and parameters as possible, Yutai Heavy Industry may adjust and correct the text expression, picture effect and other contents of the above page in real time to match the actual product performance, specifications, index, spare parts and other information.

3. Due to real-time changes in product batches, production and supply and other factors, if the above modifications and adjustments are necessary, no special notice will be given. Please consult us for relevant information.

Key words:

Previous Page

Next Page

Previous Page

Next Page

Related Products

Related Products

Welcome your message consultation