Filling intelligent control system

Wisdom Filling Data Center

Storage, classification, statistics and analysis of various production process parameters, test data, statistical data and management data in the filling production process;

Optimize filling production, improve production efficiency and filling indicators, and form a smart filling data center.

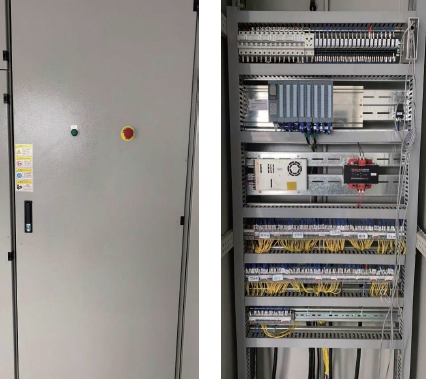

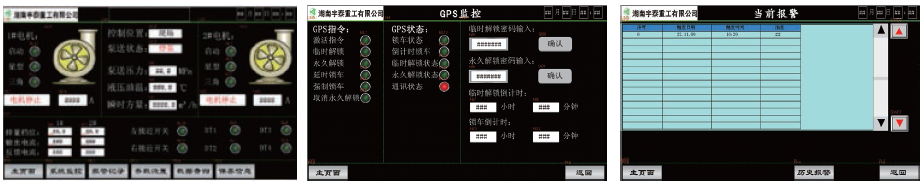

One-key filling control system

Intelligent "one-key filling" control system industrial control computer, DCS/PLC control system, sensors, communication network equipment, etc., equipped with Yutai customized development of one-key filling software;

Self-inspection, self-adjustment and automatic correction of production fluctuation;

Realize accident prevention mechanism and emergency treatment;

Significantly reduce the number of staff and labor intensity;

Improve process stability, index reliability and production safety.

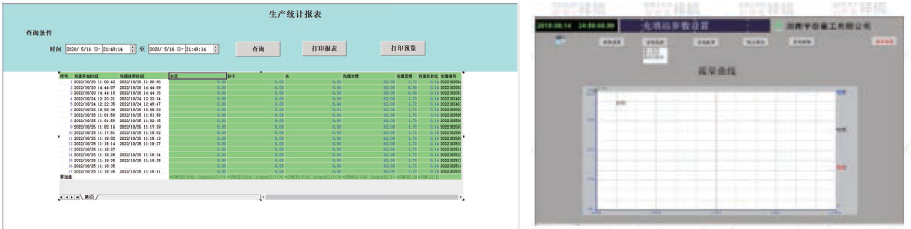

Production Data Management and Analysis System

Based on the mine filling management software developed by Yutai;

Use advanced big data analysis technology, data visualization technology and mobile application technology to create intelligent filling;

Meet the requirements of intelligent, professional, refined, flat, real-time field management;

Data collection, analysis and sharing: filling station data platform;

Data analysis, early warning and visualization: make data dynamic through flexible and vivid charts; Data visualization multi-terminal display meets the needs of mobile phone, PC and large screen multi-terminal display, and grasps basic production data anytime and anywhere.

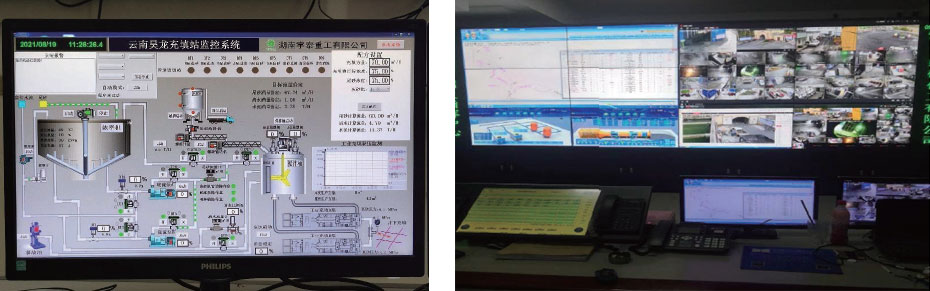

Emergency Treatment and Condition Monitoring System

In case of emergency, the control system shall be linked with the video system;

The alarm video picture is automatically pushed to the operator, and the operator can quickly and intuitively understand the actual situation on site and perform emergency dispatch.

intelligent report management system

Customized production reports, to achieve digital, paperless production management covering class, daily, monthly reports; covering equipment management reports;

Covering empty area management report; Covering production operation records;

Covers cost statements such as energy consumption, glue powder usage, etc.

3D Digital Twin Display System

Comprehensive measurement and analysis of filling station;

The use of virtual reality, 3D modeling and simulation and information platform and other technologies, to achieve a full range of filling site display, to bring users an immersive special experience, enhance the user's perception of experience and the enterprise's scientific and technological image, the filling station for a full range of display.

Attachments:

Key words:

Previous Page

Related Products

Related Products

Welcome your message consultation