New Material Study Case

Case 1: Cemented filling of iron ore with full tailings (2010)

| ash-sand ratio | Mass concentration/% | cementitious material | Uniaxial compressive strength (MPa) | |

| 7 days | 28 days | |||

| 1:4 | 67.5 | ordinary portland cement | 0.86 | - |

| 1:4 | 67.5 | composite portland cement | 0.56 | - |

| 1:4 | 67.5 | JW-I type adhesive powder | 4.66 | 9.94 |

Case 2: Cemented Filling of Iron Ore with Full Tailings (2015)

| Number |

ash-sand ratio |

Mass concentration/% |

cementitious material |

ash-sand ratio |

7-day flexural strength (MPa) |

7 days compressive strength (MPa) |

| WY01 |

1:8 |

54 |

Cement P.C32.5 |

1:8 |

0.000 |

0.000 |

| WY02 |

1:8 |

54 |

JW-I type adhesive powder |

1:8 |

1.400 |

1.475 |

| WY03 |

1:8 |

54 |

JW-I type adhesive powder |

1:8 |

1.875 |

1.813 |

| WY04 |

1:9 |

54 |

JW-I type adhesive powder |

1:9 |

1.625 |

1.638 |

| WY05 |

1:8 |

54 |

JW-I type adhesive powder |

1:8 |

1.569 |

1.951 |

| WY06 |

1:8 |

54 |

JW-I type adhesive powder |

1:8 |

1.569 |

1.541 |

| Note: The test block No. WY01 broke in the middle during the test, and no strength was detected. The flexural strength and compressive strength of 7 days were zero, that is, the test block with cement added failed to solidify. |

||||||

Case 3: Tungsten Mine Full Tailings Cemented Filling (2019)

| Serial Number |

cementitious material |

Concentration (%) |

ash-sand ratio |

Bending strength/MPa |

Compressive strength/MPa |

||

| 3 days |

7 days |

3 days |

7 days |

||||

| 1 |

Glue 1# |

73 |

1:4 |

0.18 |

3.12 |

||

| 2 |

Glue 2# |

73 |

1:4 |

0.20 |

0.46 |

0.90 |

3.61 |

| 3 |

Glue 3# |

73 |

1:4 |

0.19 |

0.46 |

1.05 |

3.89 |

| 4 |

Glue 4# |

73 |

1:4 |

0.23 |

0.47 |

1.20 |

4.03 |

Case 4: Phosphate Mine Full Tailings Cemented Filling (2022)

| ash-sand ratio |

Mass concentration/% |

cementitious material |

Compressive strength/MPa |

|

| 7 days |

28 days |

|||

| 1:8 |

72 |

Cement |

0.544 |

0.888 |

| 1:8 |

72 |

β-Glue Phosphorus Powder |

0.376 |

1.236 |

| 1:8 |

72 |

JW-T adhesive powder |

0.242 |

1.498 |

| 1:10 |

70 |

Cement |

0.544 |

0.760 |

| 1:10 |

70 |

β-Glue Phosphorus Powder |

0.290 |

0.760 |

| 1:10 |

70 |

JW-T adhesive powder |

0.408 |

1.314 |

Case 5:HMS-III soil heavy metal stabilization/solidifying agent

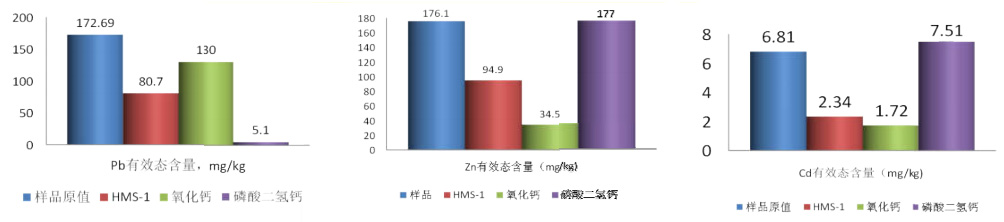

Comparative study of HMS-1 and other commonly used curing agents (lime, phosphate)

Compared with the other two commonly used curing agents, the optimized formula of HMS-1 has the most balanced remediation effect on contaminated soil, and can be used as a soil heavy metal stabilization/curing agent.

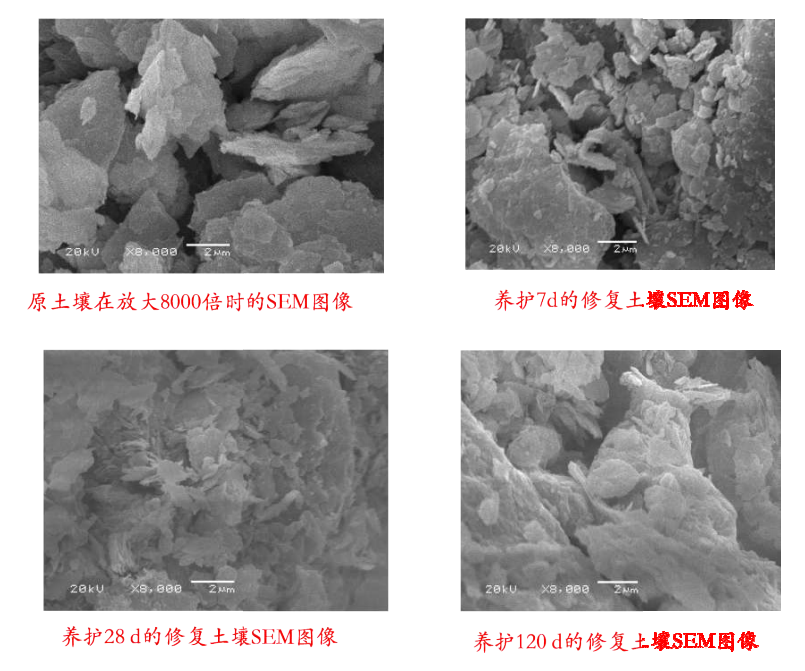

Stabilizing/curing agent and contaminated soil according to the mass ratio of 1:4 stirring and mixing evenly, curing to the age of 90 days, soil remediation pH value close to the original soil, effective state cadmium, lead, zinc, reduce the amount of 66.37%, 57.15%, 64.08%.

Attachments:

Key words:

Previous Page

Previous Page

Next Page

Related Products

Related Products

Welcome your message consultation