Contrastive Analysis of S Conversion Swing Tube Valve Pump and Lifting Cone Valve Pump in Filling Industrial Pump

Release time:

2021-07-01

Source:

Author:

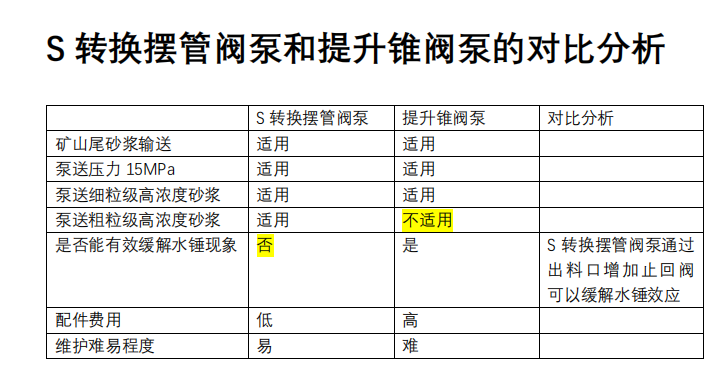

Comparative Analysis of S-Conversion Swing Pipe Valve Pump and Lift Cone Valve Pump

At present, there are two types of distribution valves for filling industrial pumps used in the field of mine tailings filling. One is an S-conversion pendulum valve, and the other is a poppet valve.

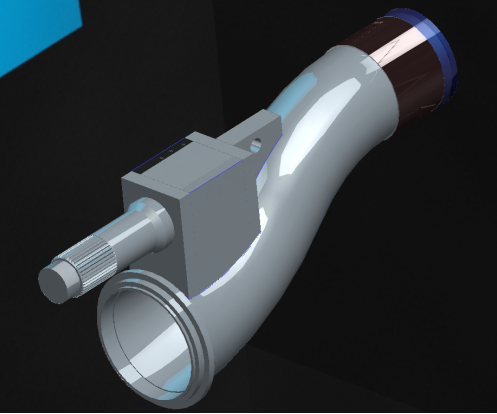

The structure is shown in the following figure:

Fig. 1 Structure of S Switching Swing Pipe Valve Pump

Features of S-conversion pendulum valve

Features of S-conversion pendulum valve

Large size barrier-free access for the best flow of 1. materials

1. The S-conversion swing tube has a large cross section, no obstacles, and no restrictions on the passage of large foreign bodies with a particle size up to 2/3 of the outlet size;

2. S swing tube system is extremely insensitive to foreign objects;

3. When the S-pendulum tube is switched, the end face of its nozzle and the glasses plate are closely attached to each other with a plane and pushed by friction. Granular materials with large particle size can be cleaned by the cutting ring along the plane of the glasses plate without being crushed.

2. automatic sealing function greatly reduces wear

1. Under the action of the conveying pressure, the cutting ring is pressed on the glasses plate. As the delivery pressure increases, the sealing effect automatically improves;

2. The S-conversion swing tube has only one sliding metal sealing point;

3, strong wear parts (hard alloy embedded layer) to maximize the service life;

3. very few wearing parts, reducing the cost of spare parts

1, wear parts replacement is simple, the required equipment downtime is short, improve availability;

2. By re-adjusting the S-conversion swing tube, the wear-resistant parts can be fully utilized to reach its utilization limit.

3. The orifice of the swinging S-conversion swing tube is a flat surface, which is automatically adjusted by the compression of the rubber spring after wear.

4. open large-diameter inlet

1. The upper part of the hopper adopts an open inlet, and the filling slurry prepared by the stirring equipment directly flows into the hopper. The hopper has a large diameter and a large volume, which is convenient for the conveying cylinder to suck materials.

2. Open hopper, the inside of the hopper will not produce negative suction pressure and overpressure caused by excessive slurry.

During the switching process of 5. S-conversion swing tube, there will be a short-term state of penetration between the discharge side and the inlet side of the conveying cylinder, resulting in intermittent slurry conveying, and microscopic material return phenomenon and water hammer phenomenon will occur under high-pressure conveying conditions.

Figure 2 Lifting cone valve pump structure diagram

Features of poppet valve

1., a hydraulic-driven poppet valve is used to realize the conversion of feeding and discharging of the conveying cylinder, and the interruption time of conveying caused by the conversion of feeding and discharging is very short, so as to ensure that there is no material return phenomenon under high-pressure conveying conditions and alleviate the phenomenon of water hammer.

2. lift valve pump is particularly suitable for metal mine fine tailings and filling high concentration of long-distance transportation;

3. poppet valve pump into the material diameter is small, delivery cylinder suction is prone to negative pressure phenomenon, suction shape is not strong;

The sealing structure of the pump head of the 4. lift valve pump adopts a conical valve disc and valve seat structure. Coarse particles of materials will be mixed between the valve disc and the valve seat, resulting in lax sealing and slurry jumping.

Comparative Analysis of S-Conversion Swing Pipe Valve Pump and Lift Cone Valve Pump

Conclusion:

1, lifting cone valve pump can meet the working conditions S conversion swing valve pump can meet, otherwise not necessarily;

2. The pumping of coarse-grain high-concentration tail mortar can only choose S-conversion swing pipe valve pump;

hunan yutai heavy industry, is a professional engaged in filling industrial pump, paste filling station set research and development, design, production in one of the manufacturers. If you need to know more about the filling of industrial pumps and related content, welcome to contact us; 18774995599.

Key words:

Real-time information

-

2024-07-13