Several Low-cost Tailings Cemented Filling Methods

Release time:

2020-11-23

Source:

Author:

Solid waste cementing filling is a cementing filling method with mine solid waste as filling material and cement, or mining solid waste as cementing material. Metal mine tailings, including red mud, phosphorus slag, phosphogypsum, etc., waste rock is the two main solid waste. Mine solid waste cemented filling mainly refers to the mine waste rock, tailings as a filling material of cemented filling. This filling method makes full use of the mine solid waste, can greatly reduce the filling cost filling, improve the filling efficiency, especially can reduce the bulk of the mine solid waste emissions, so for the promotion of the application of cemented filling mining methods to solve the difficult mining bed mining technical problems provide a strong support.

Waste rock cementing filling is based on mining waste rock as a filling aggregate, and cement or solid waste cementing material as a cementing material. The filling mode of filling into the goaf after gravity mixing has been seen. Its technical features are fully dual-purpose mine natural grading within the mine. The waste stone, through the waste stone aggregate and gel material diversion input and gravity mixing process, to fill the mechanical properties of the filling body as the goal, to achieve the best water filling, to minimize energy consumption and glue consumption. Because the waste stone is used as the main filling aggregate, the cost of filling is lower than that of fine sand cemented filling, and the waste stone cemented filling body is better than the mortar cemented filling body. After the waste rock cemented filling material is filled into the stope, it hardly seeps water, which can avoid the environmental pollution caused by the underground.

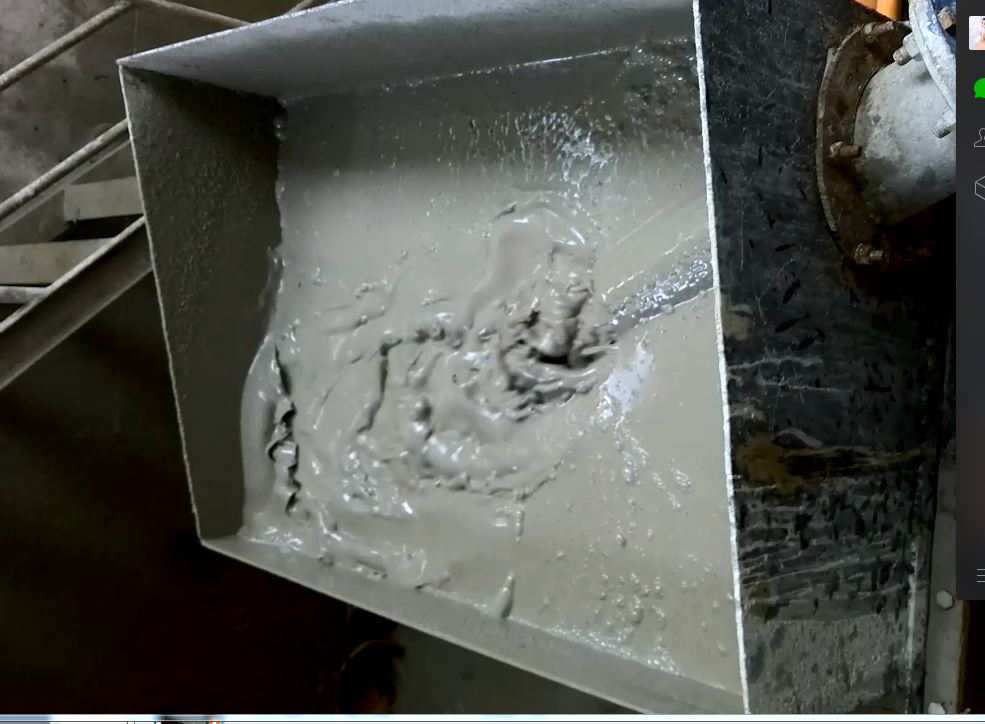

Tailings cemented filling refers to the cemented filling method using flotation tailings as aggregate, including graded tailings cemented filling and full tailings cemented filling. Graded tailings cemented filling requires a large amount of tail mud discharge. Full tailings cemented filling refers to the cemented filling method of using full-grain tailings without grading and desliming as the filling aggregate, due to its technical difficulty, in21Century began to mature applications in mines at home and abroad. For the whole tailings filling aggregate, due to the high mud content, the cement will be dehydrated and lost at low concentration, resulting in excessive cement consumption, serious deterioration of the underground operating environment, and even difficult solidification due to segregation classification,. Therefore, it is required to carry out full tailings cemented filling in a high concentration state. The narrow full tailings cemented filling method does not coarsen the aggregate, and is mainly transported by gravity and can be pumped. The filling slurry does not dehydrate after being filled into the stope, and only a small amount of bleeding. Generalized full tailings cemented filling method, can be coarse aggregate. The whole tailings added with coarse aggregate shall be filled with filler, mainly by pumping, and can also be transported by gravity under suitable conditions.

Hunan Yutai Heavy Industry is a professional manufacturer engaged in paste filling research. The company has a large number of professional and technical personnel and has built a special environmental management laboratory. If you need more information about tailings filling, please call us at 18774995599.

Key words:

Real-time information

-

2024-07-13